What bothers me greatly about this discussion, this is precisely the attitude, belief, ideology, orthodoxy that is remarkably prevalent among moto wrencher folks. This is precisely why cooling hose joints in these systems and cooling hoses fail. Then, there is heat of up to and over 200 degrees F on the hose material, add thermal cycling and the actual stress on these connections is a LOT more than it appears. That 10-15 psi applied to that area of a typical cooling hose ID is no longer a small amount of force.

Well, it is only 10 to 15 psi, with such low pressure, why should any of this matter? It went out of production for a while, then returned due to demand. Parker introduced a beading tool that worked well.

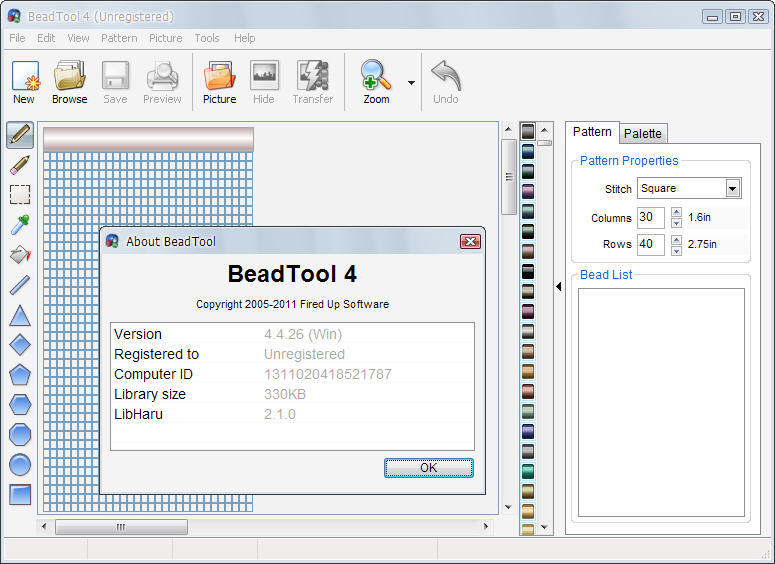

Beadtool 4 connection failed portable#

History of portable tube beaders goes back to the World War Two era when flex hose to beaded tube connections were common. It is very important to use the proper lubricant with any of these rolling tube beaders due to the friction involved, specially when beading aluminum or stainless steel which has a tendency to gall with increasing friction.

The tube header made for the Miata coolant reroute project has 0.005" clearance between the header housing and tube ID, makes a nice bead due to the tight tolerances. This problem worsens as the gap between beader body to tube ID increases. Problem with these tube beaders, if there is too much clearance between the ID of the tube and header housing (about 0.010" to 0.02", dependent of tube ID and beader body) the three chrome steel balls have a risk of mis-tracking resulting in a overlapping bead that will not seal properly. Aircraft spruce has been selling these for at least a decade These chrome steel ball bead rollers have been around for a while, at least a decade. Particularly when replacing the tubes at the same time.the layout up front could be reconfigured to better fit the new radiator. Use of hose connectors between sections of metal tubes could also be applied to the installation of the VW (Scirocco) radiator, with both hose fittings on the same end of the rad. And steps can be taken to lessen that as well. As mentioned previously, vibration/movement between the two tube ends is the only thing that might accelerate wear of these short hose sections. So there really isn't much to be concerned about using these as tube connectors. Or consider the matrix of hoses on any modern vehicle.

They are very similar to the short 90* hose between the thermostat housing and the water return tube off the back of the water pump. And the use of these sections of hose as connectors is no different than any cooling system hose. Maybe even three stacked washers, the middle one slightly larger diameter? This should give a smoother, more rounded "hump" to the bead.Īs Mike noted, the cooling system pressure is limited by the radiator cap's rating (e.g. With the pictured "DIY" vice-grip bead tool, I think it could be improved by using something thicker and with a more rounded profile instead of a washer for the inner die portion. The price for the larger sizes gets a little high but still much less than the traditional "crank" style tube bead formers. That was just a quick example I noticed, there may be other sizes from other companies (although 1 3/8 is not a really common size). Regarding those tube bead rollers from Summit.

0 kommentar(er)

0 kommentar(er)